Before this page was written, Vintage Radioactive Old lenses was the subject of two different posts during 2024.

I only now find the time to compile a text which is in part the synthesis and/or completion of these two posts, connected to this topic which has raised so much interest.

So let’s start with a bit of history. Not only speaking about photography…

Vintage radioactive old lenses

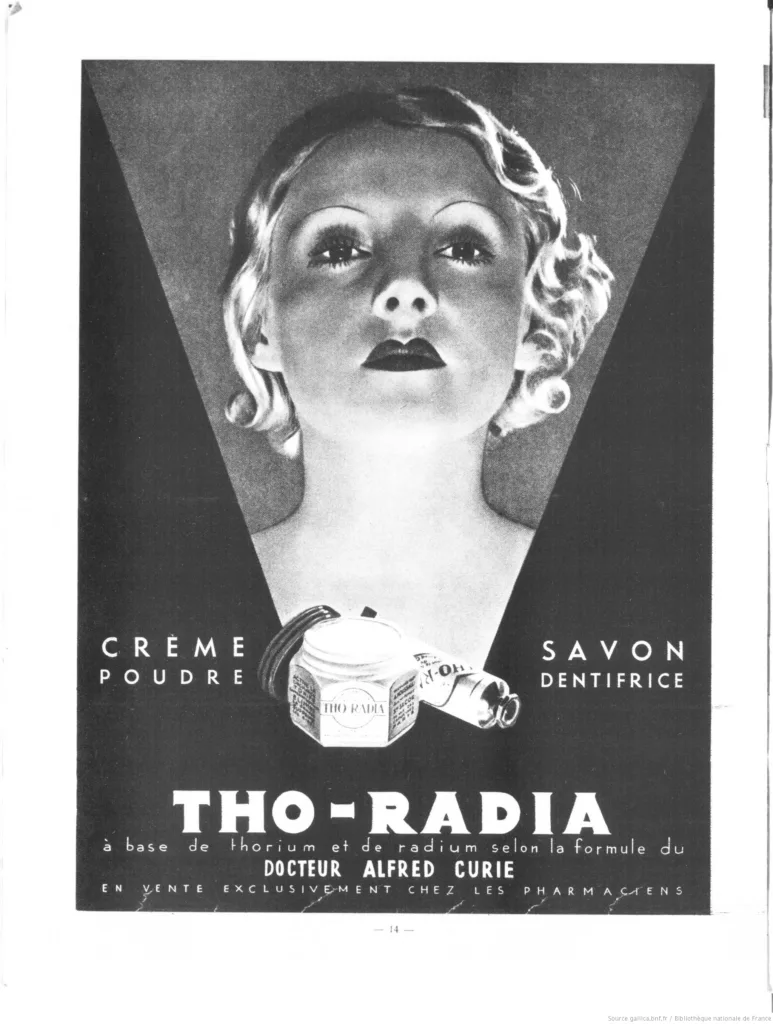

In the 1930s, powdered cream (THO-RADIA) were even produced which included RADIO.

Suppositories to improve sexual performance (VITA RADIUM) always with RADIO element.

Even a RADIO broadcaster! …which produced radioactive water.

(Image from: Commons Wikimedia)

License Attribution; Cinémagazine, 14 février 1935, CC BY-SA 4.0 https://creativecommons.org/licenses/by-sa/4.0, via Wikimedia Commons

It seems clear that the “fad” for radioactive products had spread at the beginning of the last century and had in some way infected our ancestors.

Studies relating to the atom, nuclear energy, and everything connected to it, had certainly contributed to the subject’s great media exposure. I don’t think it should be surprising at this point and in this historical context that lenses were designed and produced that used radioactive elements.

The element probably most used in the photographic field for the production of lenses was undoubtedly THORIUM, even if it was not the only one.

In the last century, besides thorium, other radioactive elements were used in the production of photographic lenses to improve their optical properties. The main elements are:

- Lanthanum: Although not inherently radioactive, it is important to mention because many glasses containing thorium also contained lanthanum oxide. This improved the refractive index and dispersive properties of the glass.

- Uranium: Uranium oxide was used in some glasses for photographic lenses, particularly during the 1940s and 1950s. This gave the glass a yellow or green tint and improved its optical properties.

- Potassium-40: Although present in minimal amounts and not intentionally added for optical purposes, natural potassium contains a small fraction of potassium-40, which is radioactive.

The use of these radioactive elements has been discontinued due to health and safety concerns related to radioactivity. Today, modern technologies and materials allow for the production of high-quality optical glass without the use of radioactive substances.

It’s interesting to understand the reason linked to my photographic passion. For which THORIUM was mainly added to Vintage Radioactive Old Lenses.

The reason is that THORIUM limits light reflections in the lenses. Thorium oxide was added to glass as it made it possible to create lenses with a high refractive index combined with low light dispersion.

Thorium glass was also used in ocular lenses for microscopes. Although in those quantities the thorium produced alpha and beta rays that the skin could easily shield. The same could not be said for the cornea of the eyes which could be damaged. Thorium lenses were produced between the 1940s and 1980s, but have since been banned.